Preventive maintenance with Chemitek Solar anti-static protection

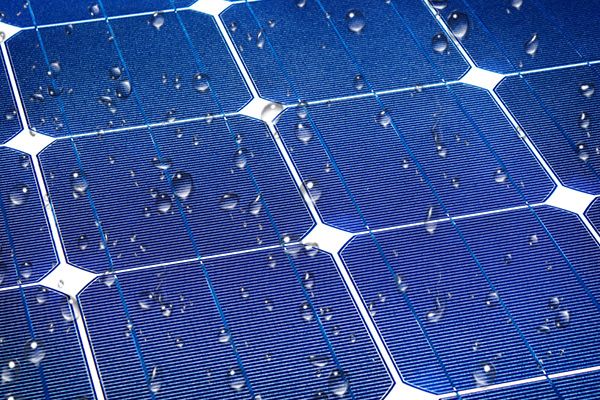

Preventive maintenance is not just the electrical part of the subtle panels. Preventive maintenance can also be the cleaning and the prevention from the contaminants reaching the panels.

There can be a lot of industrial residues such as as cement, dust, paint and other types of contaminants that will damage your solar panels and the ARC (Anti Reflective Coating) for example. That ARC is quite delicate and most of the times, to remove this type of contaminants from your solar panels, you need drastic measures such as scrapers, acids or solvents. Using a anti-static coating will prevent you from using these drastic measures and will protect your panels.

An anti-static coating is a type of coating that is applied to the surface of solar panels to reduce the buildup of static electricity. Static electricity is a type of electrical charge that builds up on surfaces due to the friction between two materials. It can be caused by a variety of factors, such as wind, dust, and other environmental conditions. In the case of solar panels, static electricity can cause small particles of dirt and dust to stick to the surface, reducing the efficiency of the panels and making them more difficult to clean.

Anti-static coatings work by reducing the surface energy of the solar panel, making it less attractive for dust and dirt to stick to. These coatings can be made from a variety of materials, such as polymers, ceramics, or carbon. The most common anti-static coatings are silicone-based, which are widely used and have been proven to effectively reduce static buildup and dust adhesion.

Anti-static coatings are not only beneficial for solar panels' performance, but also for their longevity. When dust and dirt accumulates on solar panels, it can cause scratches, corrosion, and other types of damage over time. An anti-static coating can help to protect the surface of the solar panel from this damage, which can help to extend its lifespan.

Additionally, anti-static coatings can help to reduce the need for frequent cleaning, which can save time and resources.

It is important to note that not all anti-static coatings are created equal and it is important to choose a coating that is specifically designed for use on solar panels. Some coatings may not be able to withstand the high temperatures and UV radiation that solar panels are exposed to, which can lead to problems such as cracking or peeling. It is important to choose a high-quality coating that has been tested and proven to be effective on solar panels.

At Solarco Cleaning, we only use Chemitek Solar products in our daily operations. The only chemical we know about that's 100% safe and approved by module manufacturers. I can't recommend them enough!

- Kim Verduyckt | owner Solarco Cleaning BV

Click on the icon to share this post

You might also like

Expert Tips